This blog provides self-explanatory, basic pneumatic circuits with only a single cylinder. Direct control of a single-acting cylinder Indirect control of a single-acting cylinder Speed control of a single-acting cylinder Direct control of a double acting cylinder Indirect control of a double acting cylinder Speed control of a double acting cylinder Memory control of a... Continue Reading →

How to Develop Multiple-actuator Pneumatic Circuits Using the Shift Register Method?

Textbook on ‘Pneumatic Systems and Circuits -Advanced Level’ By Joji Parambath The textbook presents information on the classification, constructional features, working and essential terms and definitions, sizing, and safety and maintenance aspects of hydraulic accumulators. The book uses the SI system of units. Please click on the image link to go to the Amazon.com Website... Continue Reading →

Relay Controllers Vs PLC Controllers – An Insight into their Circuitry

The basic concepts of a relay control system and a PLC control system are highlighted in this article with the help of a circuit diagram. Assume that an electro-pneumatic system is used to obtain an industrial work operation. The system consists of a pneumatic power part and an electrical control part. The electrical control part... Continue Reading →

Understanding Air Compressors – Part 3

[Note: Part 1 of this article presents the basics of air compressors. Part 2 presents the classification and construction details of air compressors. Part 3 presents a brief about the sizing of air compressors.] Sizing Air Compressors Sizing an air compressor for an application requires a logical sequence of actions. The following steps highlight a... Continue Reading →

Understanding Air Compressors – Part 2

[Note: Part 1 of this article presents the basics of air compressors. Part 2 presents the classification and construction details of air compressors. Part 3 presents a brief about the sizing of air compressors.] Classification of Compressors In a positive displacement compressor, air is confined within an enclosed space where it is compressed by decreasing... Continue Reading →

Understanding Air Compressors – Part 1

[Note: Part 1 of this article presents the basics of air compressors. Part 2 presents the classification and construction details of air compressors. Part 3 presents a brief about the sizing of air compressors.] A power source in a pneumatic system generates and distributes compressed air to all of its actuators. A compressor converts mechanical... Continue Reading →

Know the Difference between Gauge Pressure and Absolute Pressure

Two pressure scales measure pressure values in fluid power systems: a gauge scale and an absolute scale. The gauge pressure is the pressure indicated by a pressure gauge. It is a measure of the pressure with reference to the atmospheric pressure (1.013 bar or 14.7 psi) and it is not with reference to the absolute... Continue Reading →

Configuring a Typical Pneumatic System

The schematic diagram of a typical pneumatic system is in the accompanying figure. Basically, the system is composed of a power source, control valves, and work elements. The power source can broadly be classified into compressed air generation, primary air treatment, storage, air distribution, and secondary air treatment. A compressor is a device for converting... Continue Reading →

Know the Most Economical Pressure in Pneumatics

What is the Most Economical Pressure in Pneumatics? Pneumatic systems have been developed and progressed comparatively as low-pressure systems. Pneumatic air-consuming devices such as cylinders and rotary actuators are designed for a maximum operating pressure of 8 to 10 bar [115 to 145 psi]. However, practical experience has shown that 6 bar [90 psi] is... Continue Reading →

The Essence of Programmable Logic Controllers (PLCs)

A programmable logic controller (PLC) is a modern device that can control the work process in a machine or an appliance. The operations involved in the work process are carried out by actuators such as electric motors, pneumatic actuators, hydraulic actuators, etc., which are controlled by final control elements such as contactors, solenoid valves, etc.... Continue Reading →

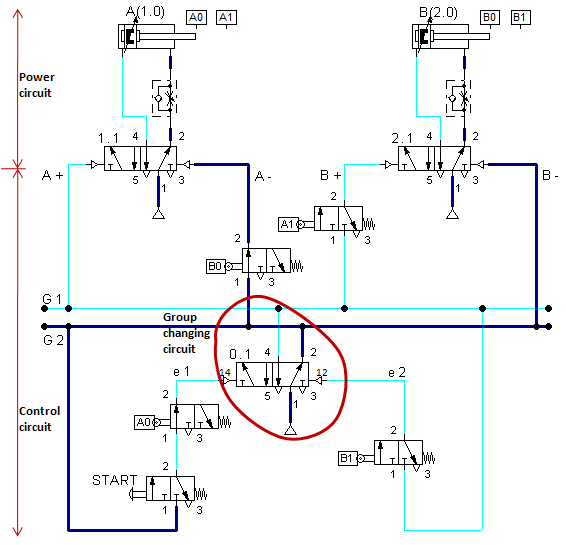

How to Develop Multiple-actuator Pneumatic Circuits Using the Cascade Method?

Most practical pneumatic systems involve multiple actuators (cylinders, semi-rotary actuators, etc.), which carry out the desired control tasks when operating in specified sequences. Double-pilot directional control (DC) valves are used as final control elements to control the forward and return strokes of the actuators. Sensors are used to confirm the actuator positions and provide signals... Continue Reading →

Fluidsys Training Centre Pvt. Ltd., Bangalore

This is the post excerpt.