Fluidsys Training Centre Pvt Ltd., Bangalore Long-term Course Hydraulic and Pneumatic Systems – Advanced Level We are excited to introduce our long-term course on Pneumatics and Hydraulics. Duration: 12 weeks (4 to 6 hours per day, Monday to Friday) / Flexible timings Course Dates (2025): Please see our course calendar Eligibility: ITI / Diploma /... Continue Reading →

Understanding Air Compressors – Part 3

[Note: Part 1 of this article presents the basics of air compressors. Part 2 presents the classification and construction details of air compressors. Part 3 presents a brief about the sizing of air compressors.] Sizing Air Compressors Sizing an air compressor for an application requires a logical sequence of actions. The following steps highlight a... Continue Reading →

Understanding Air Compressors – Part 2

[Note: Part 1 of this article presents the basics of air compressors. Part 2 presents the classification and construction details of air compressors. Part 3 presents a brief about the sizing of air compressors.] Classification of Compressors In a positive displacement compressor, air is confined within an enclosed space where it is compressed by decreasing... Continue Reading →

Understanding Air Compressors – Part 1

[Note: Part 1 of this article presents the basics of air compressors. Part 2 presents the classification and construction details of air compressors. Part 3 presents a brief about the sizing of air compressors.] A power source in a pneumatic system generates and distributes compressed air to all of its actuators. A compressor converts mechanical... Continue Reading →

Know the Difference between Gauge Pressure and Absolute Pressure

Two pressure scales measure pressure values in fluid power systems: a gauge scale and an absolute scale. The gauge pressure is the pressure indicated by a pressure gauge. It is a measure of the pressure with reference to the atmospheric pressure (1.013 bar or 14.7 psi) and it is not with reference to the absolute... Continue Reading →

Configuring a Typical Pneumatic System

The schematic diagram of a typical pneumatic system is in the accompanying figure. Basically, the system is composed of a power source, control valves, and work elements. The power source can broadly be classified into compressed air generation, primary air treatment, storage, air distribution, and secondary air treatment. A compressor is a device for converting... Continue Reading →

Know the Most Economical Pressure in Pneumatics

What is the Most Economical Pressure in Pneumatics? Pneumatic systems have been developed and progressed comparatively as low-pressure systems. Pneumatic air-consuming devices such as cylinders and rotary actuators are designed for a maximum operating pressure of 8 to 10 bar [115 to 145 psi]. However, practical experience has shown that 6 bar [90 psi] is... Continue Reading →

Hydraulic Fluid Contamination & its Control

Hydraulic fluids are subjected to various kinds of contamination (particles, water, air, compounds, and biological). Contaminants can affect fluids' physical and chemical properties. If the contaminants are not monitored or controlled, the fluid is likely to fail. A complete range of 36 textbooks, in Paperback & Kindle eBooks Editions, on Pneumatics and Hydraulics, under the... Continue Reading →

The Essence of Programmable Logic Controllers (PLCs)

A programmable logic controller (PLC) is a modern device that can control the work process in a machine or an appliance. The operations involved in the work process are carried out by actuators such as electric motors, pneumatic actuators, hydraulic actuators, etc., which are controlled by final control elements such as contactors, solenoid valves, etc.... Continue Reading →

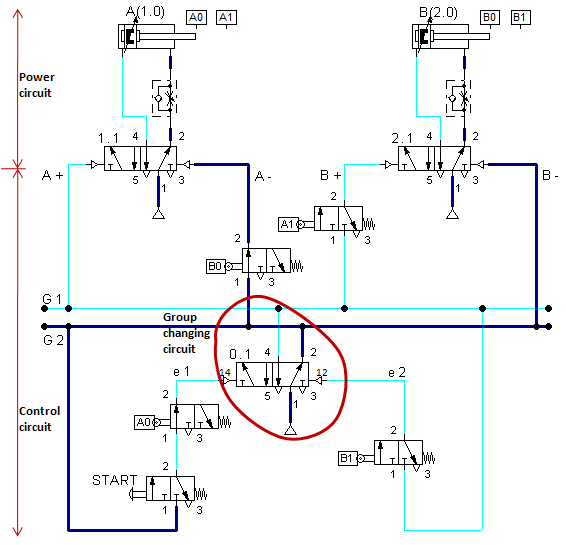

How to Develop Multiple-actuator Pneumatic Circuits Using the Cascade Method?

Most practical pneumatic systems involve multiple actuators (cylinders, semi-rotary actuators, etc.), which carry out the desired control tasks when operating in specified sequences. Double-pilot directional control (DC) valves are used as final control elements to control the forward and return strokes of the actuators. Sensors are used to confirm the actuator positions and provide signals... Continue Reading →

Relay-based Electro-hydraulic Systems

In the electrical actuation of a hydraulic valve, the necessary actuating force is obtained electrically with the help of a solenoid. The off-centre core of the solenoid coil is pulled towards the centre of the coil when the electric current is passed through it. This discrete movement of the core is used to actuate the... Continue Reading →

Pressure Control Valves in Hydraulic Systems

The article looks at the basics of pressure control valves for educational use and is presented here to refresh your memory. Hope you can recall the functions, circuits, and applications of pressure control valves. Pressure control valves are used in hydraulic systems to obtain pressure-related control functions. Pressure control valves can be categorized into: (1)... Continue Reading →

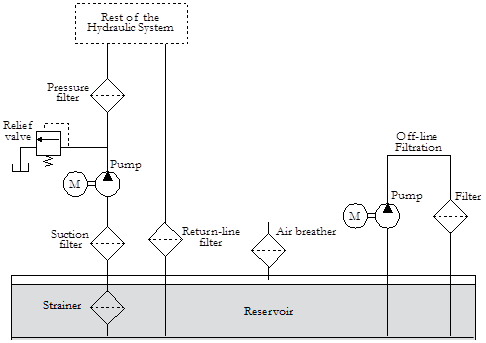

Hydraulic Filters

Hydraulic filters are vital components in hydraulic systems, ensuring they operate at peak performance and reliability. These filters effectively remove contaminants such as dirt, dust, and metal particles from the hydraulic fluid, which can otherwise lead to system failures or reduced efficiency. This article delves into the various construction features of hydraulic filters, highlighting the materials... Continue Reading →

Load Sensing Hydraulic Systems

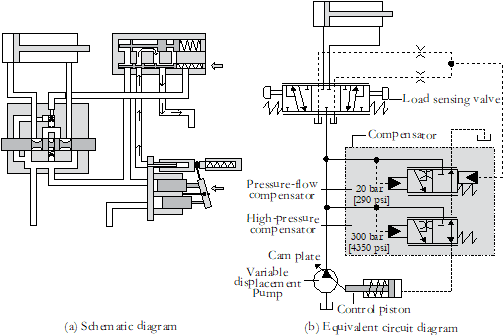

The hydraulic system with a load sensing feature provides only the flow and pressure required by the connected load. Controlling both the pressure and the flow allows for a significant reduction in losses, improvement of circuit efficiencies, and enhancement of the system's service life. A Typical Load Sensing System The basic load sensing system typically... Continue Reading →

Electro-hydraulic Servo Valve Systems

Hydraulic systems driven by servo valves provide highly accurate control over enormous forces. A servo valve system consists of a transducer, a servo amplifier, a servo valve, and an actuator with a connected load. It is a closed-loop system used to precisely control the output (load) parameter, such as position, velocity, or force, in response... Continue Reading →

What is Cavitation?

Cavitation is a harmful condition that occurs in a hydraulic system component like a pump or a valve when the existing space in the working component is not filled with the system fluid. It is the formation and collapse of vapor or air bubbles in the pumped fluid as it passes through the component. Undetected... Continue Reading →

Training

Source: Training

Five Typical Applications of Hydraulics

The use of fluid power is widespread in many stationary and mobile applications. Many of the operators, technicians, and engineers are not well-versed in the operational, maintenance, and safety aspects of fluid power. Therefore, systematic training is essential for them to handle fluid power systems. Modern hydraulic technology can be used to make the brakes... Continue Reading →

Fluid Power – Fascinating Points (#1)

Fluid power provides the muscle for various work operations in stationary and mobile applications. As we can see, the use of fluid power is widespread in many applications. However, many operators, technicians, and engineers are ignorant of the operational, maintenance, and safety aspects of fluid power. Therefore, proper training is essential for handling fluid power... Continue Reading →

Fluidsys Training Centre Pvt. Ltd., Bangalore

This is the post excerpt.