Hydraulic fluids are subjected to various kinds of contamination (particles, water, air, compounds, and biological). Contaminants can affect fluids’ physical and chemical properties. If the contaminants are not monitored or controlled, the fluid is likely to fail.

A complete range of 36 textbooks, in Paperback & Kindle eBooks Editions, on Pneumatics and Hydraulics, under the Fluid Power Educational Series, authored by Joji Parambath, has been released. For more details, please visit

Contamination in Hydraulic Fluids

Contaminants are the natural enemy of hydraulic components and systems. 70 to 80% of the failures are due to the adverse effects of contaminants.

Solid Particles

It includes hard particles (dust, dirt, silica, wear metals) and soft particles (elastomers, fibres).

Chemical Contaminants

They are formed by the breakdown of additives, due to chemical reactions.

Water

Water is introduced into the fluid by the condensation of humid air.

Air

Air can exist either in the ‘free state’ or in the entrained state. An air pocket trapped in a part of the system is an example of free air. Air bubbles typically less than one mm in diameter dispersed in the fluid medium is the entrained air.

Contamination Control

Contamination control involves the removal of particles, water, air, sludge, acid, and chemicals.

Air contamination can be eliminated by providing air bleeds and diffusers. Water can be removed by installing a water-removal filter or a vacuum dehydrator. Heat can be removed by installing a heat exchanger.

Fluid Cleanness Standards

CThe particle size classification standard is the ISO 11171:2010. The standard for specifying the contamination concentration levels is the most widely used ISO 4406:1999.

Particle Size Classification Standard

The standard ISO 11171 specifies the three-dimensional size of particles (i.e., 4, 6, and 14 microns), for representing the concentration levels of fine as well as coarse particles.

Fluid Cleanliness Level Standard

ISO 4406:1999 specifies the cleanness level of a given sample of fluid by a three-number range code representation, such as 18/16/14, based on the number of particles of size greater than 4, 6, and 14 microns respectively, present in one ml of the sample fluid.

Typical Cleanliness Level Targets

Hydraulic equipment manufacturers, fluid suppliers, and fluid power associations have established target fluid cleanliness levels applicable for the general types of hydraulic components.

| Components |

Range code |

| Flow control valves, cylinders |

17/18/15 |

| New, unused fluid |

17/18/15 |

| Gear pumps/motors |

20/17/14 |

| Vane pumps/motors |

19/16/13 |

| Piston pumps/motors |

19/16/13 |

| Directional & pressure control valves |

19/16/13 |

| Proportional valves |

18/15/12 |

| Servo valves |

17/14/11 |

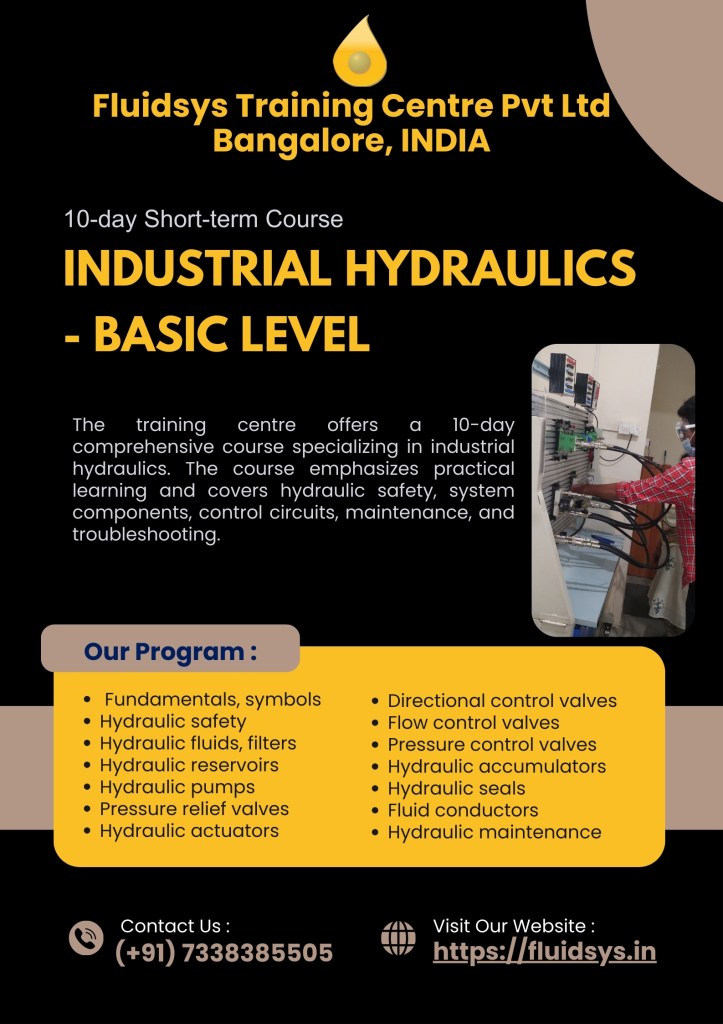

Fluidsys Training Centre Pvt. Ltd., Bangalore, India

Mob: +917338385505

email: info@fluidsys.org | Website: https://fluidsys.org

Leave a comment